- On-demand InkJet Printing System

CraftPix with numerous functions unique to digitalization

that was not possible with the analog method.

Useful Features

Serialization and Barcode

1. Various numbering functions to assure product traceability

You can now easily add date, lot code, barcode and serial number to production panels, individual PCBs, test coupons, and other products.

This will allow your customers traceability which is just another added value the CraftPix offers.

Your choice of man readable, code 39 and matrix barcodes are available.

2D barcode reader (handheld type)

2. 2D barcode printable with CraftPix series

CraftPix series can print three types of codes: Data Matrix, QR codes and micro QR codes. The area required for printing depends on the number of characters. If printing with CraftPix series, recognition is possible when printed in the same sizes or larger as shown in the table on the right. While the recognition can be done with a 2D barcode reader, it can also be done with the code reading application installed on a cellphone or smartphone.

| Minimum print size for 2D barcodes (when droplet volume is 3.5pl). *Print size will vary depending on the type of text, ink and surface condition of the media. |

||||

| 2D Barcode | Example | Number of Character | ||

| 10 | 20 | 30 | ||

| Data Matrix (square) |  | 0.03” (0.8 mm) | 0.039” (1.0 mm) | 0.047” (1.2 mm) |

| Data Matrix (rectangle) |  | 0.047 x 0.023” (1.2 x 0.6 mm) | 0.078 x 0.02” (2.0 x 0.5 mm) | 0.063 x 0.03” (1.6 x 0.8 mm) |

| QR Code |  | 0.051” (1.3 mm) | 0.055” (1.4 mm) | 0.055” (1.4 mm) |

| Micro QR Code |  | 0.039” (1.0 mm) | 0.039” (1.0 mm) | 0.043” (1.1 mm) |

Optional Print Defect Detection Optional

1. Automatic nozzle check system

As a countermeasure against degradation of ink and nozzle defects while printing, an automatic nozzle check system using high-speed image processing technology is installed to detect various defects. While performing the print on the panel, 1mm wide line (coupon) is printed on the panel margin area. Once printing is completed, the printed coupon is scanned at high speed with the built-in camera to check the quality as the shuttle table is ejected. If the coupon quality result in FAIL, the following judgment result is displayed on the operation screen. When print quality of the coupon is PASS, nothing will be displayed.

2. Print Result Inspection System

Optional automatic detection of print defects. After printing is complete, while the board is being ejected, two visual inspection cameras positioned around the table scan the board. By scanning the board on ejection, the additional time required is a mere one second. Defects that cannot be prevented by the automatic nozzle system, such as human error or dirt on the workpiece, can also be detected.

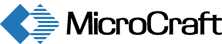

Wide-field navigation camera Optional

Example of screen display

In addition to the standard alignment camera, a wide-field navigation camera with a viewing range of approximately 3.9” (100mm) can be installed. Wider visible range on the screen simplifies operation when teaching the height detection position and the first alignment position. Furthermore, an image showing the current visible range is displayed on the screen, making it easy to determine the panel location on the shuttle table. Operator can switch between alignment camera and wide-field navigation camera automatically when necessary.

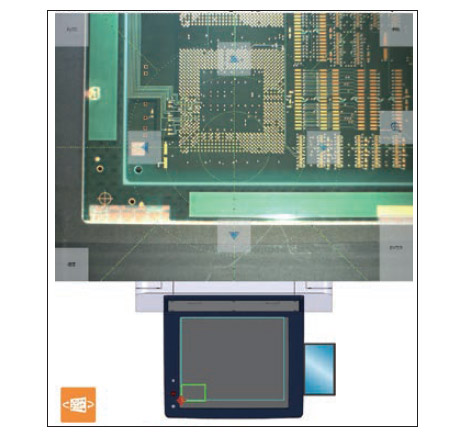

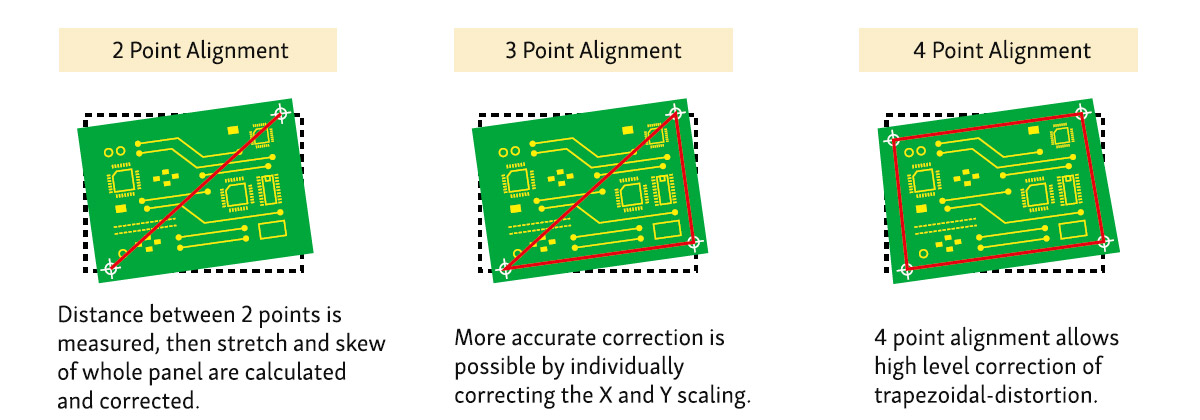

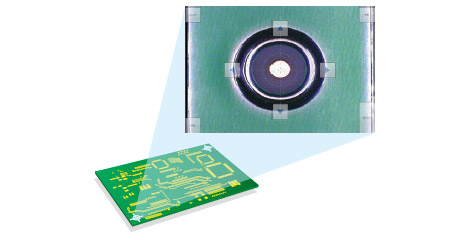

Auto-Alignment

Auto-alignment makes high-speed and high-accuracy printing possible.

With multiple alignment features available, you can choose from 1 to 4 alignment points. X, Y and theta rotation are measured and data is rasterized for precise image printing. Furthermore, each separate or single-image piece can be aligned with “Piece Alignment”

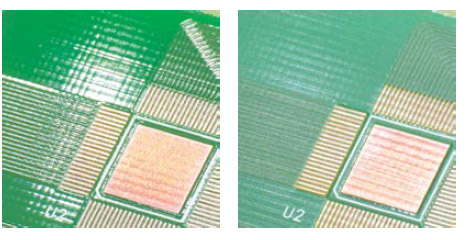

Glossy/Matte Surface Finish

Left: Glossy Finish

Right: Matte Finish

CraftPix can offer two different types of surface finish. When shiny surface is required, our Glossy Surface Finish is suitable. We can assure shinny and smooth glazed surface finish. Bright color tone with high saturation will showcase very rich appearance to your PCB. In case shiny finish is unrequired, we recommend to use our Matte Surface Finish. Unlike glossy finish, we can offer very calm tone of surface appearance without mirror like shininess.