- Moving Probe Tester

Fully Automated 24hrs unattended testing now possible with AL series

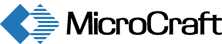

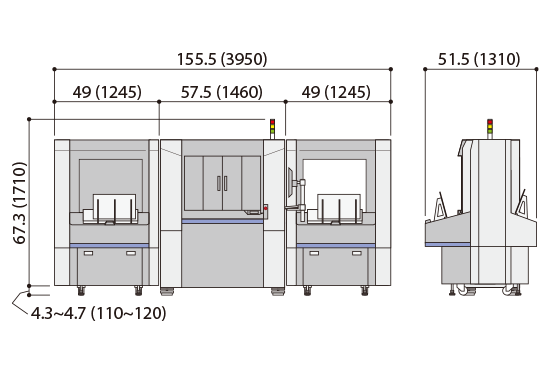

AL Series (4 Probe System / Vertical Type)

Standard Model / High Accuracy Model / Super High Accuracy Model

E4M / E4H / E4S6151G-AL NEW

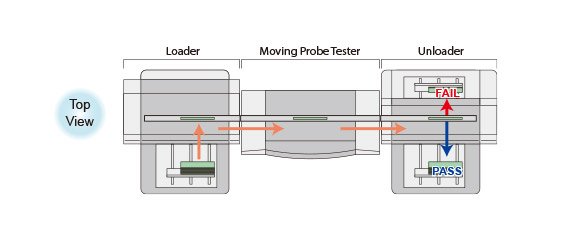

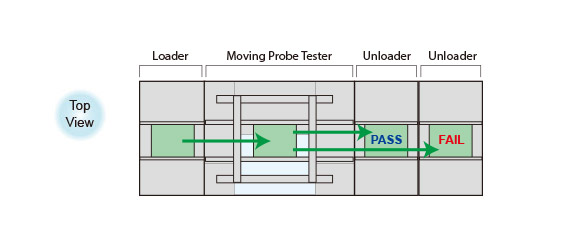

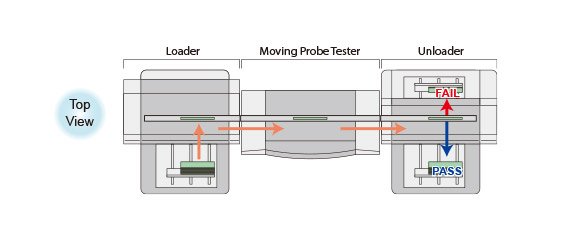

Vertical type EMMA with autoloader. Once the substrate is set in the autoloader section, the suction pad automatically picks up the substrate and transports it to the conveyor rail. The substrate on the conveyor rail is transported to the inspection section in the center to start inspection. After the inspection is completed, the substrates are immediately transferred to the unloader, and good and bad substrates are sorted into their respective stackers, eliminating the risk of mixing.

* Conventional E4M, E4H, E4S cannot be connected to AL series.

• Max. Stackable Boards:

§ Autoloader: 200 pcs

§ Unloader: PASS Boards 200 pcs, FAIL Boards 60 pcs

(§ when board thickness is 1.6mm. Max. stackable weight: 80kg)

• Inclusion of stamp unit is available. Optional

• Supports multi-image boards

Detailed Specification

| E4M6151G-AL | E4H6151G-AL | E4S6151G-AL | |

|---|---|---|---|

| Max. Test Area | 24 x 20” (610 x 510 mm) |

24 x 20” (610 x 510 mm) |

24 x 20” (610 x 510 mm) |

| Max. Transferable Panel Size | 24.4 x 20.4” (620 x 520 mm) |

24.4 x 20.4” (620 x 520 mm) |

24.4 x 20.4” (620 x 520 mm) |

| Number of Probes | 2 Front, 2 Rear |

2 Front, 2 Rear |

2 Front, 2 Rear |

| Min. Board Size | 2.4 x 3.9” (60 x 100 mm) *1 |

2.4 x 3.9” (60 x 100 mm) *1 |

2.4 x 3.9” (60 x 100 mm) *1 |

| Min. Transferable Panel Size | 3.9 x 3.9” (100 x 100 mm) |

3.9 x 3.9” (100 x 100 mm) |

3.9 x 3.9” (100 x 100 mm) |

| Max. Board Thickness | 0.02–0.2” (0.5–5.0 mm) *2 |

0.02–0.2” (0.5–5.0 mm) *2 |

0.02–0.2” (0.5–5.0 mm) *2 |

| Max. Transferable Weight | 6.6 lbs. (3 kg) *3 |

6.6 lbs. (3 kg) *3 |

6.6 lbs. (3 kg) *3 |

| Clamp Margin | 0.12–0.39” (3.0–10 mm) |

0.12–0.39” (3.0–10 mm) |

0.12–0.39” (3.0–10 mm) |

| Untestable Area | 1 mm from edge of clamp area *4 |

1 mm from edge of clamp area *4 |

1 mm from edge of clamp area *4 |

| Repeatable Accuracy *5 | ±0.16 mil (±4 µm) |

±0.16 mil (±4 µm) |

±0.08 mil (±2 µm) |

| Resolution | 0.08 mil (2 µm) |

0.08 mil (2 µm) |

0.04 mil (1 µm) |

| Min. Pad Pitch | 4.0 mil (100 µm) *6 |

2.0mil (50 µm) *6 |

2.0mil (50 µm) *7 |

| Min. Pad Size | 1.2 mil (30 µm) *8 |

0.8 mil (20 µm) *8 |

0.6 mil (15 µm) *9 |

| Test Voltage | Continuity Test: 0–10 V |

Continuity Test: 0–10 V |

Continuity Test: 0–10 V |

| Test Current | Continuity Test: 2.5 µA–150 mA |

Continuity Test: 2.5 µA–150 mA |

Continuity Test: 2.5 µA–150 mA |

| Clamp System | Pneumatic Clamp |

Pneumatic Clamp |

Pneumatic Clamp |

| Alignment Camera | 2 Front, 2 Rear |

2 Front, 2 Rear |

2 Front, 2 Rear |

| Printer | External |

External |

External |

| Air Supply: Pressure | 0.5 MPa |

0.5 MPa |

0.5 MPa |

| Air Supply: Volumetric flow rate | 5.3 ft³/min. (150 ℓ/min.) |

5.3 ft³/min. (150 ℓ/min.) |

5.3 ft³/min. (150 ℓ/min.) |

| Power Supply *11 Single Phase AC200–240 V 50/60 Hz |

15 A |

15 A |

15 A |

| Weight | 2425 lbs. (1100 kg) *12 |

2535 lbs. (1150 kg) *12 |

2535 lbs. (1150 kg) *12 |

| Dimensions [ unit: inch(mm) ] |  |

||

| Required System | 1)Control PC & Monitor 2)PC & Monitor for Test Data Editing. * 1) and 2) can be completed in one PC. * Please inquire our sales for PC specification. |

||

| Software | EMMA2020 for Control PC is included, but all other software is optional (supporting OS are Windows 10 / Windows 11) | ||

| Probe Type | Different types of probes were designed to address specific needs. Please contact our sales for more information on each probe types in selecting ideal probe. | ||

| Operating Conditions | 70–75°F (21–24°C), 30–70% relative humidity * Do not use under the environment that has heavy condensing, dust, vibration, and/or corrosive gas. Atmospheric Dew Point: −14°C or below (at 0.7 Mpa, dew point is 15°C or below) Oil Mist Concentration: 1 mg/㎥ (ANR) or below |

||

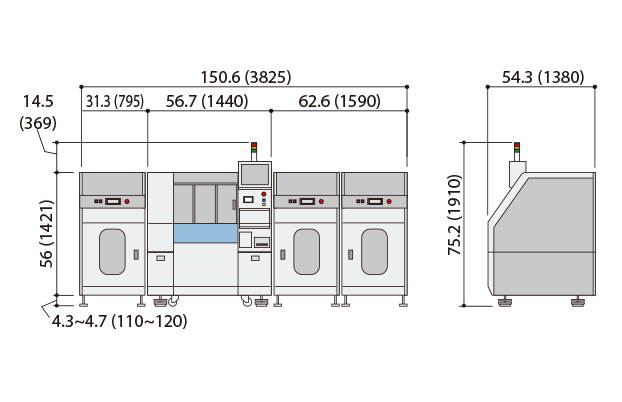

AL Series (4 Probe System / Horizontal Type)

High Accuracy Model

F4H4033G-AL NEW

This is a horizontal type EMMA with autoloader. In-line type transfer using conveyor rails makes it possible to connect to various transfer lines.

• Max. Stackable Boards:

§ Autoloader: 400 pcs

§ Unloader: PASS Boards 400 pcs, FAIL Boards 400 pcs

(§ when board thickness is 1.6mm. Max. stackable weight: 80kg)

• Inclusion of stamp unit is available. Optional

• Supports multi-image boards

Detailed Specification

| F4H4033G-AL | |

|---|---|

| Max. Test Area | 15.7 x 13” (400 x 330 mm) |

| Max. Transferable Panel Size | 16.5 x 13.4” (420 x 340 mm) |

| Number of Probes | 2 Upper, 2 Under |

| Min. Board Size | 2 x 2” (50 x 50 mm) *1 |

| Min. Transferable Panel Size | 3.9 x 3.5” (100 x 90 mm) |

| Max. Board Thickness | 0.04–0.12” (1.0–3.0 mm) *2 |

| Max. Transferable Weight | 2.2 lbs. (1 kg) *3 |

| Clamp Margin | 0.08” (2 mm) |

| Untestable Area | 2mm from edge of clamp area *4 |

| Repeatable Accuracy *5 | ±0.12 mil (±3 µm) |

| Resolution | 0.08 mil (2 µm) |

| Min. Pad Pitch | 2.4 mil (60 µm) *6 |

| Min. Pad Size | 1.2 mil (30 µm) *7 |

| Test Voltage | Continuity Test: 0–10 V Isolation Test: 250 V *8 |

| Test Current | Continuity Test: 2.5 µA–150 mA |

| Clamp System | Pneumatic Clamp |

| Alignment Camera | 2 Upper, 2 Under |

| Printer | Internal |

| Air Requirement: Pressure | 0.5 MPa |

| Air Supply: Volumetric flow rate | 10.6 ft³/min. (300 ℓ/min.) |

| Power Supply *9 Single Phase AC200–240 V 50/60 Hz |

15 A |

| Weight | 2646 lbs. (1200 kg) *10 |

| Dimensions [ unit: inch(mm) ] |  |

| Required System | 1)Control PC & Monitor 2)PC & Monitor for Test Data Editing. * 1) and 2) can be completed in one PC. * Please inquire our sales for PC specification. |

| Software | EMMA2020 for Control PC is included, but all other software is optional (supporting OS are Windows 10 / Windows 11) |

| Probe Type | Different types of probes were designed to address specific needs. Please contact our sales for more information on each probe types in selecting ideal probe. |

| Operating Conditions | 70–75°F (21–24°C), 30–70% relative humidity * Do not use under the environment that has heavy condensing, dust, vibration, and/or corrosive gas. Atmospheric Dew Point: −14°C or below (at 0.7 Mpa, dew point is 15°C or below) Oil Mist Concentration: 1 mg/㎥ (ANR) or below |

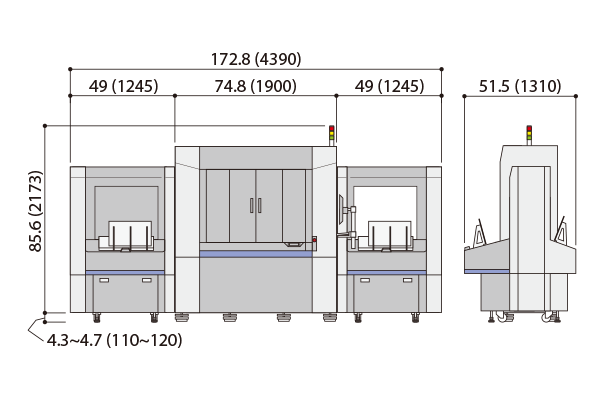

AL Series (8 Probe System / Vertical Type)

Standard Model

E8M6151G-AL / E8M6151G-AL2 NEW

Super high-speed test with 8 probes. New AL2 Model is capable of transferring two boards (size under 250 x 250 mm) at the same time to dramatically improve the throughput for smaller sized boards.

* Conventional E8M6151 cannot be connected to AL series.

Large Size Model

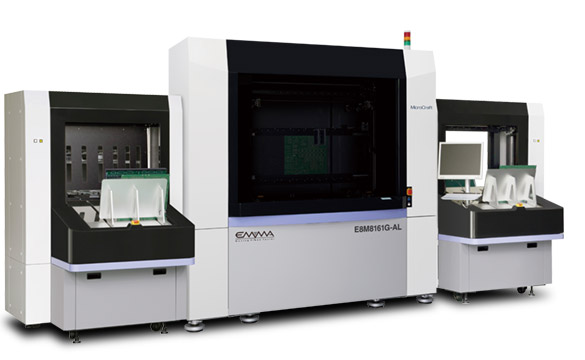

E8M8161G-AL / E8M8161G-AL2 NEW

Super high-speed test with 8 probes. Large Size Model with the maximum test area of 32 x 24” (810 x 610 mm). New AL2 Model is capable of transferring two boards (size under 250 x 250 mm) at the same time to dramatically improve the throughput for smaller sized boards.

* Conventional E8M8161 cannot be connected to AL series.

• Max. Stackable Boards:

§ Autoloader: 200 pcs

§ Unloader: PASS Boards 200 pcs, FAIL Boards 60 pcs

(§ when board thickness is 1.6mm. Max. stackable weight: 80kg)

• Inclusion of stamp unit is available. Optional

• Supports multi-image boards

Detailed Specification

| E8M6151G-AL / AL2 | E8M8161G-AL / AL2 | ||

|---|---|---|---|

| Max. Test Area | 24 x 20” (610 x 510 mm) |

32 x 24” (810 x 610 mm) |

|

| Max. Transferable Panel Size | AL: 24.4 x 21” (620 x 520 mm) |

AL: 24.4 x 21” (620 x 520 mm) |

|

| Number of Probes | 4 Front, 4 Rear |

4 Front, 4 Rear |

|

| Min. Board Size | 3.9 x 3.9” (100 x 100 mm) *2 |

3.9 x 3.9” (100 x 100 mm) *2 |

|

| Min. Transferable Panel Size | 3.9 x 3.9” (100 x 100 mm) |

3.9 x 3.9” (100 x 100 mm) |

|

| Max. Board Thickness | 0.02–0.2” (0.5–5.0 mm) *3 |

0.02–0.2” (0.5–5.0 mm) *3 |

|

| Max. Transferable Weight | 6.6 lbs. (3 kg) *4 |

6.6 lbs. (3 kg) *4 |

|

| Clamp Margin | 0.12–0.39” (3.0–10 mm) |

0.12–0.39” (3.0–10 mm) |

|

| Untestable Area | 3mm from edge of clamp area *5 |

3mm from edge of clamp area *5 |

|

| Repeatable Accuracy *6 | ±0.16 mil (±4 µm) |

±0.16 mil (±4 µm) |

|

| Resolution | 0.08 mil (2 µm) |

0.08 mil (2 µm) |

|

| Min. Pad Pitch | 4.0 mil (100 µm) *7 |

4.8 mil (120 µm) *7 |

|

| Min. Pad Size | 2.0 mil (50 µm) *8 |

2.0 mil (50 µm) *8 |

|

| Test Voltage | Continuity Test: 0–10 V |

Continuity Test: 0–10 V |

|

| Test Current | Continuity Test: 2.5 µA–150 mA |

Continuity Test: 2.5 µA–150 mA |

|

| Clamp System | Pneumatic Clamp |

Pneumatic Clamp |

|

| Alignment Camera | 4 Front, 4 Rear |

4 Front, 4 Rear |

|

| Printer | External |

External |

|

| Air Requirement: Pressure | 0.5 MPa |

0.5 MPa |

|

| Air Supply: Volumetric flow rate | 5.3 ft³/min. (150 ℓ/min.) |

5.3 ft³/min. (150 ℓ/min.) |

|

| Power Supply *10 Single Phase AC200–240 V 50/60 Hz |

20 A |

20 A |

|

| Weight | 4630 lbs. (2100 kg) *11 |

4850 lbs. (2200 kg) *11 |

|

| Dimensions [ unit: inch(mm) ] |

|

|

|

| Required System | 1)Control PC & Monitor 2)PC & Monitor for Test Data Editing. * 1) and 2) can be completed in one PC. * Please inquire our sales for PC specification. |

||

| Software | EMMA2020 for Control PC is included, but all other software is optional (supporting OS are Windows 10 / Windows 11) | ||

| Probe Type | Different types of probes were designed to address specific needs. Please contact our sales for more information on each probe types in selecting ideal probe. | ||

| Operating Conditions | 70–75°F (21–24°C), 30–70% relative humidity * Do not use under the environment that has heavy condensing, dust, vibration, and/or corrosive gas. Atmospheric Dew Point: −14°C or below (at 0.7 Mpa, dew point is 15°C or below) Oil Mist Concentration: 1 mg/㎥ (ANR) or below |

||

Function Unique to AL Series

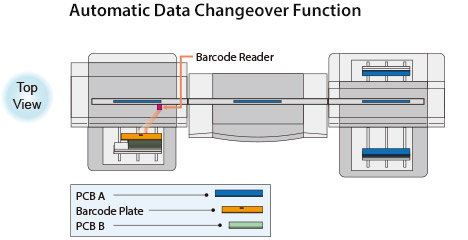

Automatic Data Changeover Function

AL series can be equipped with “Automatic Data Changeover Function” with the use of barcode. This is a convenient function for reducing trouble occurrence and saving operator’s handling time when testing various kinds of boards. This is done by placing the barcode plate between Board Group A and Board Group B on the loader. It is no longer required to enter the number of boards into the software. The loader is equipped with a barcode reader, and when the barcode plate comes to the forefront, the barcode is scanned (left picture), then the tester recognizes that Board Group B will be transferred from next test. When Board Group B is transferred, test will be performed for Board Group B. It eliminates the risk of typing errors and ensures that all tests are carried out correctly. As an option it is also possible to automatically load the data linked to the barcode.

* The plate with the barcode will not be tested, but transferred to FAIL board of unloader.

Retest function per lot.

Each defect that have been detected in the same lot are collected and when retesting, all points where defects are detected in that same lot is tested. This enables smooth re-testing without checking the test results of each board.

- Please feel free to contact us for questions regarding the machine specs, quotes, inquiries for a brochure from the following phone number or the inquiry form. The equipment seen in the lineup are customizable to address your needs.

-

- Inquiries by phone

+1-714-482-2550 - Inquiries by email

Inquiry form

- Inquiries by phone